Standard Work

Having been working as a lean consultant for a couple of decades, I

continue to be amazed at the number of times I walk through the door of an

organization undertaking some "lean" improvement who cannot give the

definition of standard work, and have never seen a standard work combination

sheet, or a standard work layout sheet.

To refresh your memory, standard work is made up of three things; takt time,

work sequence and standard work in process. Takt time is a theoretical

calculation that shows the relationship between the time available to do the

work and the volume of work to be done. You can see my earlier blog on takt

time if you want more information on this topic. Here's the link.

Takt Time - Does this apply to my process? (breakthroughhorizonsltd.blogspot.com)

Work sequence is pretty easy to understand. What is the easiest, safest, lowest cost, highest quality sequence of

tasks necessary to complete the work in a standardized way. Think of this as a

recipe. Baking a cake from the recipe on the box, is an example of the work

sequence.

Finally we need to consider the standard work in process. This is planned

inventory between steps to enable a process to flow to takt time. If we need to package chairs at a rate

of 20 minutes per chair, and the glue from the previous step takes 60 minutes to dry, then we need 3

pieces of standard work in process (60 minutes drying time divided by 20

minutes of takt time)to enable one piece flow at packing.

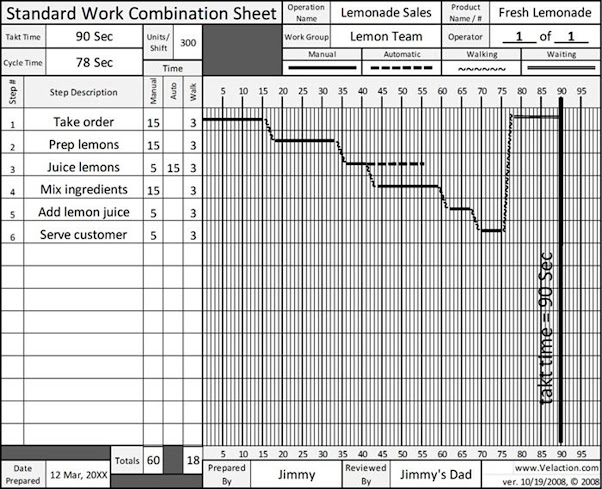

The standard work is documented on the standard work combination sheet. This is

a well aged form that shows the takt time, and the work sequence. The work

sequence is documented with standard time associated for each task which is extremely

valuable for training and auditing as well as for identifying further

opportunities for cycle time reduction. Here is an example of the standard work

combination sheet.

The standard work in process is documented on the standard work layout sheet. An example of the standard work layout sheet is shown below ( from Standard Work Templates Excel ) :

Lean Blessings;

Ron

President and Sensei

Breakthrough Horizons LTD

www.breakthroughhorizons.com

Comments

Post a Comment