Explaining the Lean Management System - Part 1 - The Key Elements

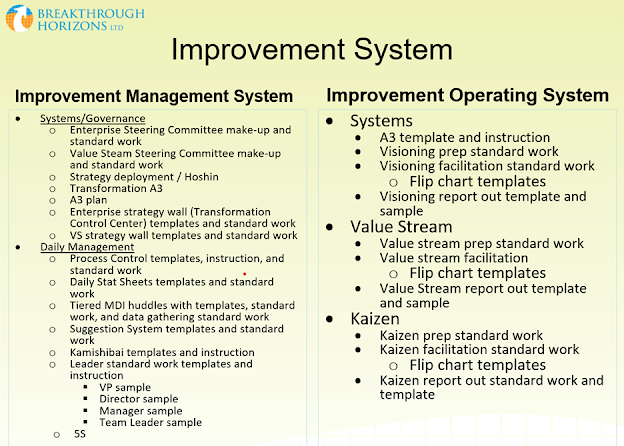

In the spirit of sharing process improvement knowledge, I am offering a small blog series explaining important pieces of a lean management system. To begin this discussion, I should share the key elements of an entire improvement system. It is sometimes helpful to break the improvement system down into two parts, although I want to emphatically state that both elements are essential to delivering sustainable, operational improvement change in both performance and culture. The two elements of the improvement system include the operating system and the management system. The operating system is used to generate breakthrough improvements through the application of the scientific method. When discussing breakthrough improvements, think 10% plus improvement. The management system is used to maintain standards, provide data, insights, and behavior to sustain gains, and can be used for incremental improvement of existing processes. While not completely comprehensive the slide below provides the key elements of the operating and the management system.

When you do an internet search on lean improvement, you will likely get information on improvement projects and kaizen workshops. These processes engage staff and leaders and through the proper application of the scientific method, can yield tremendous results. The workshop based, lean tools are the "splash" in the improvement process and get a lot of publicity, marketing, and visibility. The part of the process that gets the least visibility but is the glue that holds project success together is the management system. The daily management system and governance pieces of this management system are necessary ingredients for system wide change. The daily management system is used for product line / service line / department change.

I will start with an introduction to the daily management system. Later blogs may include management system elements of enterprise. While it might make sense to start off at the system/enterprise level, I am a big fan of learning improvement skills in a controlled environment before spreading or scaling to system level improvement. There are seven key elements to the daily management system. While all are valuable, I generally find four elements are essential in engaging all employees, building the correct improvement habits /behaviors and sustaining improvement. These four include:

1) process or production control - This is used to ensure standard work is performing as designed and to provide hourly insights into waste creeping back into the system

2) daily tiered huddles - These are used to monitor outcomes of processes aligned to true north measures

3) kamishibai task audits - These daily audits are used to satisfy your curiosity that things are operating as designed with special emphasis on key standards, best practices, compliance, safety, etc.

4) leader standard work - This practice to designed to ensure time is being spent on improvement by leaders at all levels of the organization.

In an ideal improvement journey, you should put these four elements in place six months to a year prior to performing any breakthrough improvement work. However, with a very deep sigh, most organizations want 80% improvement next week. Afterall, that is what the process improvement advertisements show. So, in practice many organizations pursue daily management concurrent with running workshops delivering breakthrough performance. In this scenario, these four elements should be on a path to being in place within six months of beginning an improvement journey.

Another word of caution. Leaders love improvement workshops because it requires change at the process level that primarily affects line staff. Leaders can "lead" while the doers "do". Leaders frequently less love the management system because it requires a major re-wiring of how leaders organize and spend their day. Leaders have to "do" the management system. Without this behavior and corresponding culture change, processes will migrate back to status quo which negates the effectiveness of the improvement system.

Next blog, we will dive deeper into the first key element of the daily management system, that being process or production control.

Lean Blessings,

Ron

Ron Bercaw, President, and Sensei

Breakthrough Horizons

LinkedIn: https://www.linkedin.com/in/ron-bercaw-882a0a8/

Comments

Post a Comment